Features:

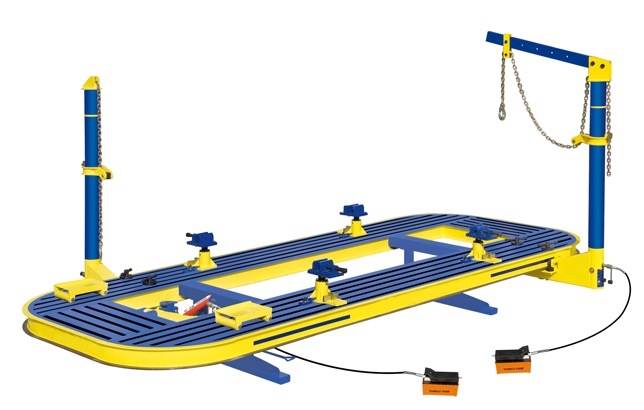

1. The platform lift for highly reasonable, flexible auxiliary light on the ramp, so that any car drive on and off more convenient.

2. Fixed-lifting platform, a Channel and mesh work bench on the 14th International standards flange beam production, utilize the auto collision repair technicians experience, plane and high intensity, no work blind area.

3. The pulling towers can work platform along the track for 360-degree rotation, unique wheel rotation, the pulling towers move more stable, more flexible.

4. The unique design of the main clamps spiral movements, in the jaw to maintain the level of state, the upper and lower pole vertically movements, fine-tuning the level of all kinds of different vehicle chassis height of rapid adjustment.

5. The jaws of main clamps unique adjustable design, only two screws, the thimble jaws, a variety of auto models that the rapid clamping firm to improve work efficiency.

6. The tools mechanical streamline design, after metal, heat treatment process, long service life and high-intensity, almost considered all deformation correction.

7. Three-dimensional coordinate measuring bridge (UMS) Measurement of the world's most advanced, seamless breakpoint, convenient operation. The global data synchronization by Mitchell and the major automotive companies to provide and maintain the latest data models.

8. The global data synchronization by Mitchell and the major automotive companies to provide and maintain the latest data models.

Specifications:

|

Frame length |

5600mm |

|

Frame width |

2232mm |

|

Frame height |

560mm |

|

Max push power for pulling tower |

95KN |

|

Rated voltage |

220v/380v |

|

Working range of pulling tower |

360° |

|

Max load bearing |

3500kg |